10 Best Cummins Fuel Filters 2026 in the United States

Winner

Fuel Filters 68157291AA and 68436631AA for a 2019-2024 Ram Truck 6.7L Cummins Diesel

The Mopar Fuel Filters 68157291AA and 68436631AA are designed specifically for the 2019-2024 Ram Truck 6.7L Cummins Diesel, ensuring compatibility and optimal performance. These genuine parts are manufactured to meet the specifications for fit, form, and function, making them reliable replacement parts. In terms of filter efficiency, they effectively remove contaminants to protect your engine, contributing to better fuel economy and performance.

Most important from

669 reviews

Doc's Diesel Dodge RAM 6.7L Cummins Fuel/Water Separator 2019-2025

Doc's Diesel Dodge RAM 6.7L Cummins Fuel/Water Separator is designed to exceed OEM standards, with a three-layer media filter offering high efficiency. This product is compatible with 2019-2023 Ram 6.7L Cummins models, ensuring a good fit for these vehicles.

Most important from

533 reviews

Fleetguard FF5825NN Fuel Filter (6 Pack)

The Fleetguard FF5825NN Fuel Filter (6 Pack) by Cummins Filtration appears to be a reliable choice for truck owners looking for replacement fuel filters. Fleetguard, being a trusted brand under Cummins, suggests good quality and compatibility with most truck models. The filter efficiency is likely to be robust, ensuring clean fuel delivery to the engine, which can enhance performance and longevity. The flow rate is optimized for trucks, likely supporting heavy-duty operations without compromising fuel delivery.

Most important from

77 reviews

Top 10 Best Cummins Fuel Filters 2026 in the United States

Winner

Fuel Filters 68157291AA and 68436631AA for a 2019-2024 Ram Truck 6.7L Cummins Diesel

Fuel Filters 68157291AA and 68436631AA for a 2019-2024 Ram Truck 6.7L Cummins Diesel

Chosen by 1238 this week

Doc's Diesel Dodge RAM 6.7L Cummins Fuel/Water Separator 2019-2025

Doc's Diesel Dodge RAM 6.7L Cummins Fuel/Water Separator 2019-2025

Fleetguard FF5825NN Fuel Filter (6 Pack)

Fleetguard FF5825NN Fuel Filter (6 Pack)

Doc's Diesel Dodge RAM 6.7L Cummins Filter Combo Kit 2019-2025

Doc's Diesel Dodge RAM 6.7L Cummins Filter Combo Kit 2019-2025

DOC'S DIESEL Dodge Ram 6.7L Diesel Fuel Filter Water Separator Set | Replaces 68197867AA 68157291AA | OEM Grade Fuel Filter and Fuel/Water Separator

DOC'S DIESEL Dodge Ram 6.7L Diesel Fuel Filter Water Separator Set | Replaces 68197867AA 68157291AA | OEM Grade Fuel Filter and Fuel/Water Separator

Buyer$ Lair Kit for Dodge Ram 6.7L Diesel Cummins Fuel Filter & Fuel/Water Seperator Set Wix WF10112 & WF10255NP for 2013-2018 Models 2500/3500/4500/5500

Buyer$ Lair Kit for Dodge Ram 6.7L Diesel Cummins Fuel Filter & Fuel/Water Seperator Set Wix WF10112 & WF10255NP for 2013-2018 Models 2500/3500/4500/5500

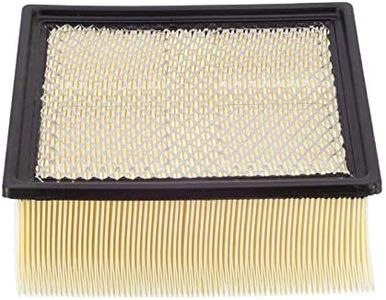

DOC'S DIESEL Ram 6.7L Cummins Oil/Air Filter Fuel Filter Water Separator Set 2013-2018 | Replaces 68197867AA 68157291AA 53034051AB 05083285AA | OEM Grade Fuel/Oil/Air Filter and Fuel/Water Separator

DOC'S DIESEL Ram 6.7L Cummins Oil/Air Filter Fuel Filter Water Separator Set 2013-2018 | Replaces 68197867AA 68157291AA 53034051AB 05083285AA | OEM Grade Fuel/Oil/Air Filter and Fuel/Water Separator

6.7L Cummins Fuel Filter Water Separator Set | Replacement for 2013-2018 Dodge Ram 2500 3500 4500 5500 6.7L Cummins Turbo Diesel Engines | Replaces# 68197867AA, 68157291AA

6.7L Cummins Fuel Filter Water Separator Set | Replacement for 2013-2018 Dodge Ram 2500 3500 4500 5500 6.7L Cummins Turbo Diesel Engines | Replaces# 68197867AA, 68157291AA

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.